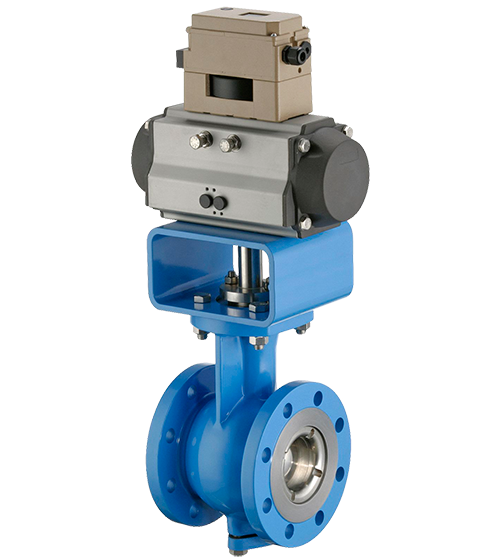

82.7 - Rotary Plug Control Valve

The Vetec 82.7 double eccentric rotary plug control valve is designed for standard and critical service applications, including process events such as erosion, abrasion, corrosion, cavitation, and flashing. The double eccentric rotary plug design increases flow capacities with only minor reduction in the pressure recovery factor making the design an ideal replacement for linear globe control designs even with cavitation and flashing process conditions present.

The Vetec 82.7 control valve has several standard options such as temperature extensions, heating jacket, special packing designs, noise attenuation and cavitation prevention trim sets, etc. The Vetec 82.7 can be assembled with a pneumatic, electric, hydraulic, or electro-hydraulic actuator also offered by the SAMSON group to complete the control valve construction. These control valves are designed according to the modular assembly principle, can be equipped with SAMSON GROUP actuators and valve accessories such as positioners, limit switches, and solenoid valves.

FEATURES & BENEFITS

- Combines Rotary Efficiency with Globe Control Excellent Performance

- Maximum flow capacity compared to globe and rotary plug with the straight through flow path

- High rangeability of up to 200:1

- Anti-blowout valve shaft design to increase reliability

- Free flow path when open with less turbulence, reduced noise and wear on the internal and guiding parts

- Double eccentric plug design eliminates friction when valve is opening/closing reduces wear in internal parts and required breakaway torques

- Double eccentric plug design allows for the more accurate control vs. other rotary valve types

- Only the highest grade materials are used for all internal components to ensure the longest possible service life

SPECIFICATIONS

- Size:1" to 10"

- ANSI Class:150 to 300

- Std. Materials:Carbon Steel, Stainless Steel, Low Temp Carbon Steel, (Special Materials on Request)

- Temperature Range:-320 to 1022℉ (-196 to 550℃)