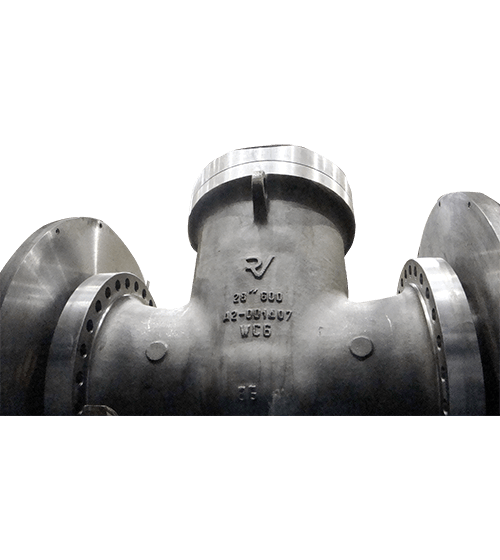

Gate Valves

The Ringo Gate Valves are offered in various versions to meet the application specifications. Standard Type Gate Valves include the solid wedge, flexible wedge, and split wedge. Parallel Slide Gate valve include through conduit, single expanding, and double expanding.

Bolted bonnet, pressure seal and cryogenic designs are available in these Ringo Gate Valves as well as designs to meet requirements of ANSI B16.34, API 600, API 6D ANSI B16.5, ANSI B16.10, API 602 and API 6A. For nuclear service ASME III, AD-Mekblatter and RCC-M are available. These control valves can be equipped with SAMSON GROUP actuators, manual operators, and valve accessories.

FEATURES & BENEFITS

- Wedge Gate Valves

- Solid Wedge Design: The wedge is made in one solid piece being the downstream side the one which seals the valve when upstream pressure push the wedge against the downstream seat.

- Flexible Wedge Design: The wedge has a machined groove in its central part providing flexibility at the disc.

- Split Wedge Design: The wedge is made in two separate parts providing high ability to seal. This design in recommended when high thermal or mechanical deformations are expected due to working conditions.

- Parallel Gate Valves

- Parallel Slide Gate Valves: For those applications when large temperature variations are expected or fast shutoff is required, this is the most ideal design. The seats are parallel and the disc has no contact with the seats during the stroke of the valve. Only at the end of the stroke the disc mechanism ensures the contact between seats and disc.

- Through Conduit: When full port gate valve is required or double block and bleed valve is mandatory this design must be used. Through conduit gate valves are designed to API 6D or API 6A. Seats are floating and sealing is made by the upstream seat which is energized by upstream pressure against the disc. These valves are piggable and normally used for oil and gas application. Both, soft seated and metal seated valves are available.

- Double Expanding Gate: Metal to Metal seated, double block and bleed are available to API 6D & API 6A.